Inženjering

Digitalizacija i izrada prototipa povećavaju produktivnost

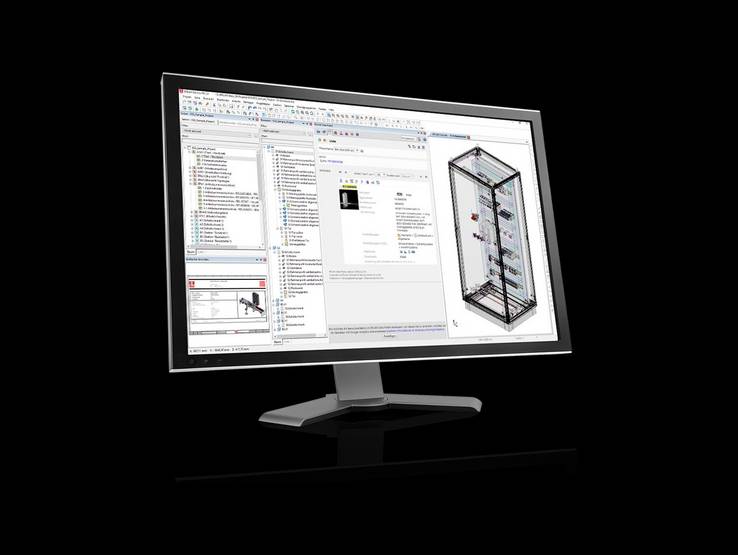

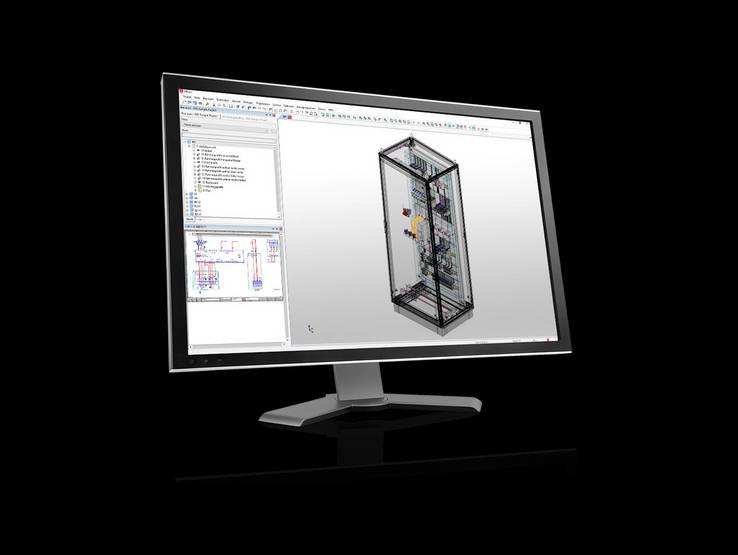

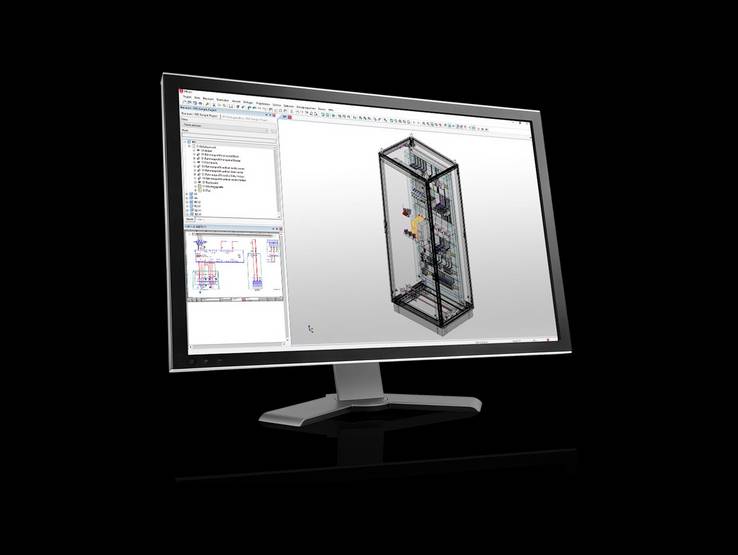

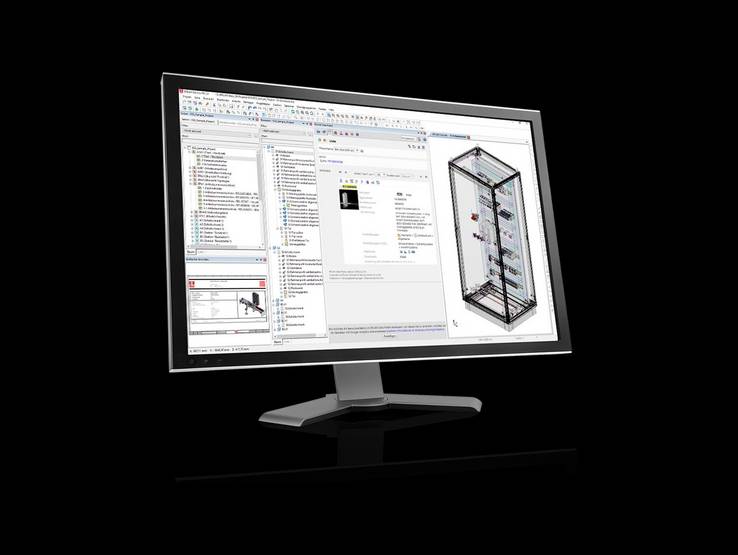

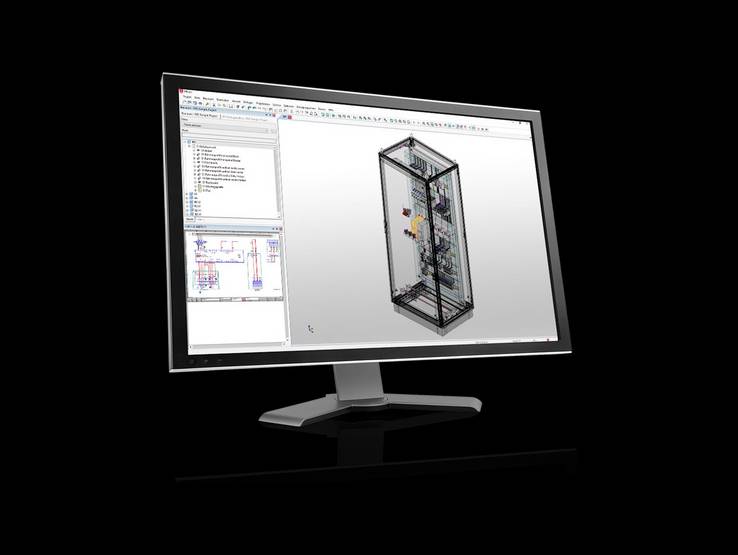

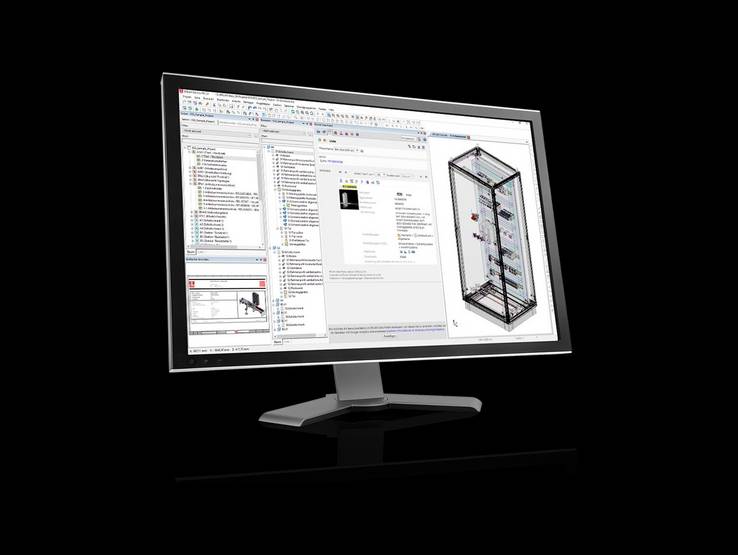

Upravljački orman je digitalno planiran i projektovan u inženjerskom odeljenju. Softverska rešenja iz EPLAN-a savršeno rade zajedno kako bi kreirali centralnu bazu podataka za Vaš ceo proces lanca vrednosti: korak po korak, digitalni blizanac proizvoda iz stvarnog života kreira se kao konzistentan model podataka. Visokokvalitetni 3D podaci prikazuju kućište i dodatnu opremu virtuelnog prototipa. Ovi podaci su dopunjeni komponentama specifičnim za projekat i informacijama o ožičenju. Kao deo ovog procesa, svi inženjerski podaci su dostupni u centralizovanom okruženju rešenja kojem se takođe može pristupiti u koracima nizvodnog procesa. Na ovaj način čak i masovno prilagođavanje može biti automatizovano i implementirano na isplativ način.

Tehničke specifikacije

Proizvođač razvodnih ormana i rasklopnih uređaja prima podatke o kupcima i potvrđuje ih u pogledu dostupnosti podataka o artiklima, kompletnosti i podobnosti za sve naredne procese, npr. u inženjeringu i pripremi rada. Ako je potrebno, podaci moraju biti pripremljeni u skladu sa tim. Štaviše, određuju se neophodne opcije kućišta i povezani dodatni koraci procesa.

Technical Consulting & Design

Suitable solutions for the enclosure, the necessary system accessories, the power distribution as well as heating, cooling or climate control are defined.

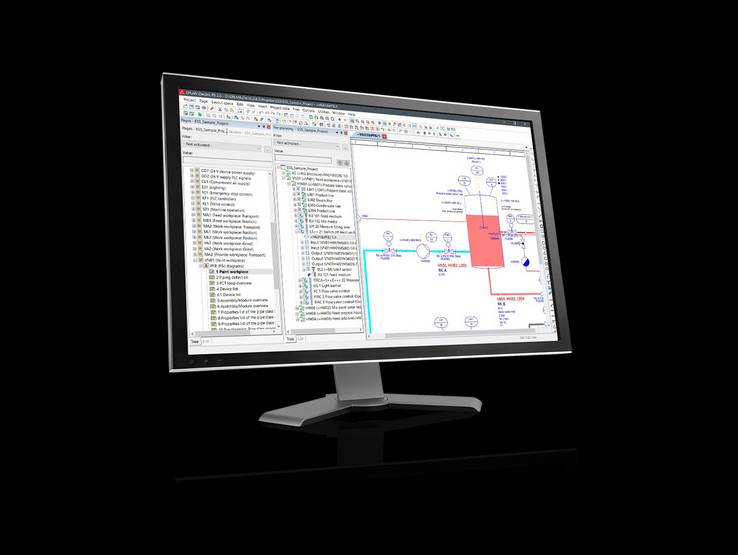

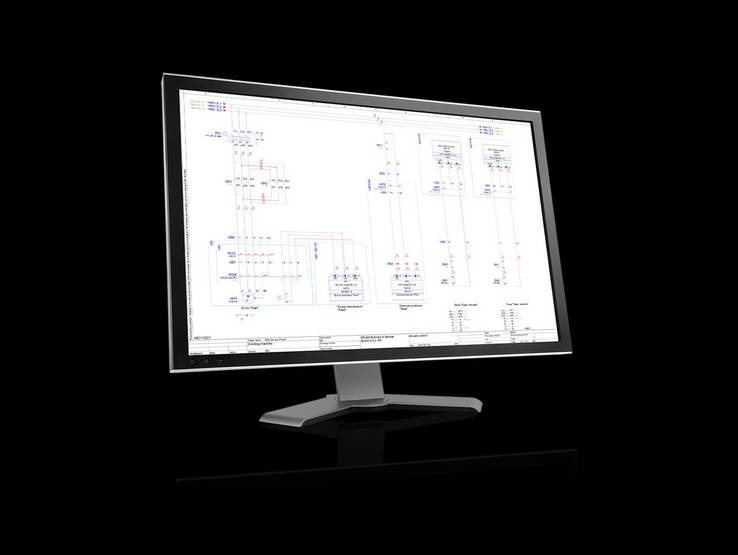

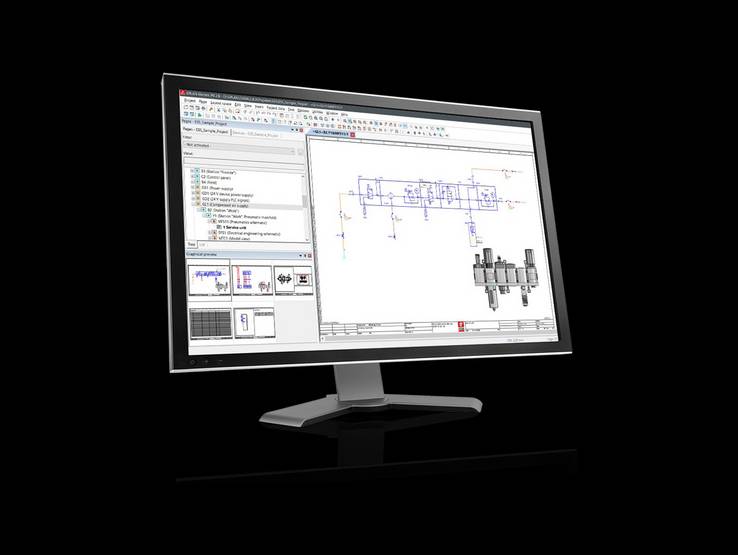

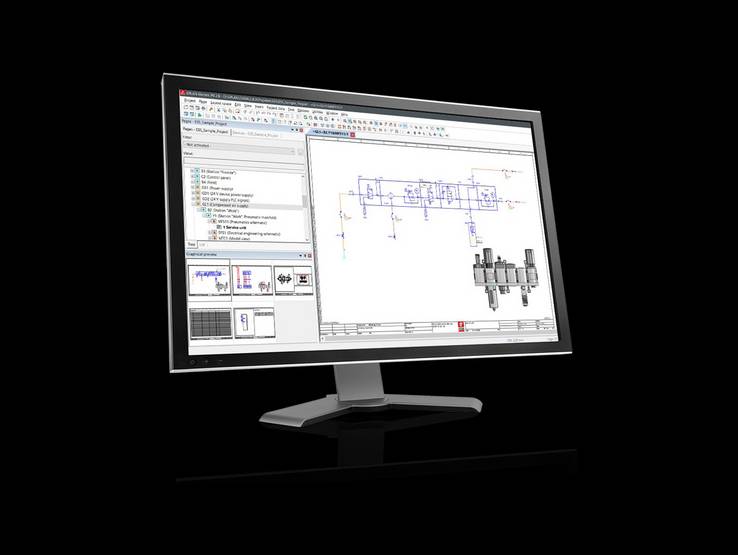

Product Functions Design

Schematic design with ECAD software – the entire value chain subsequently benefits from consistent engineering data .

Checking & Correcting

The schematic is checked for conformity to standards, completeness and correctness before it is made available for subsequent processes. This way, errors in subsequent processes, e.g. in the unambiguous designation of components or in the complete description of electrical connections, can be avoided. Ideally, this is done automatically with the support of the ECAD software.

Mechanical Infrastructure

With a view to the customer’s requirements, the location, the environmental conditions and the space required for the installation of the electrical and fluid components specified in the schematic, the appropriate type of enclosure is selected, dimensioned and supplemented with the necessary accessories.

Digital Twin

The digital twin brings great opportunities concerning manual process steps as well as for automation and digitalization of all process steps in panel building, e.g. mechanical processing, wire prefabrication, wiring and terminal assembling.

Thermal Design & Dimensioning

Customer requirements, ambient conditions at the installation site, electrotechnical components and their power dissipation as well as the defined assembly layout of the digital twin define the framework conditions for configuring and dimensioning the optimal climate control solution and the correct distribution of the air flows.